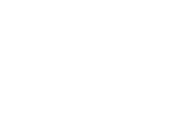

Products Introduction

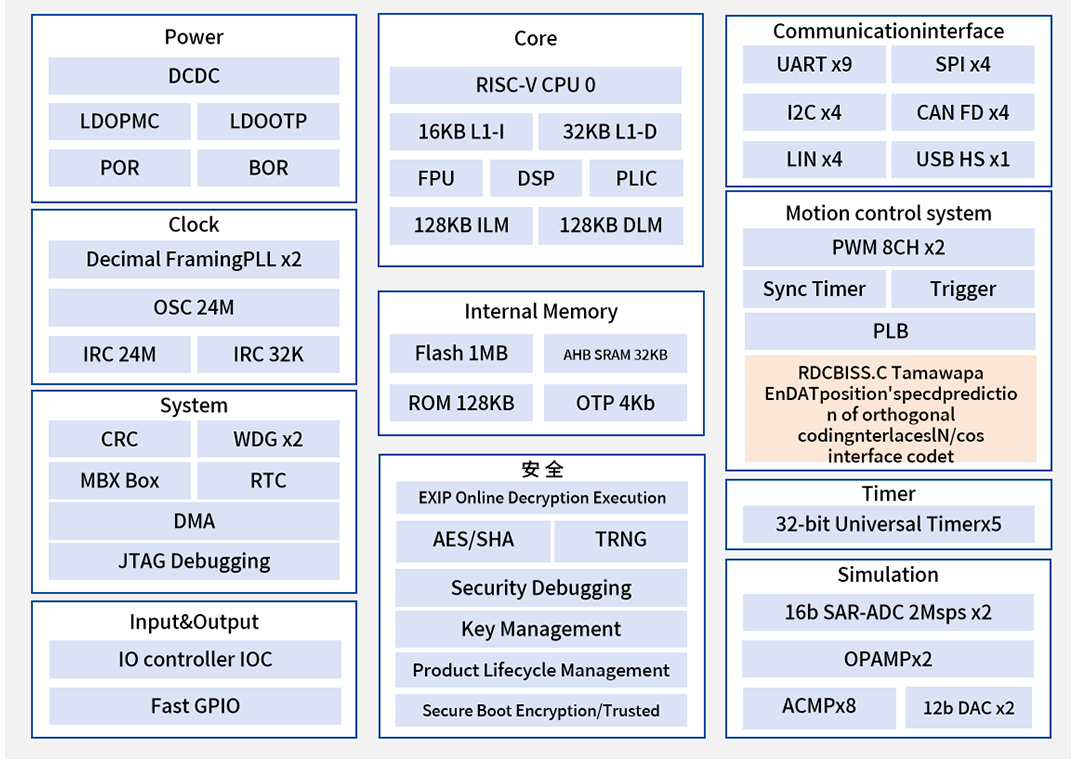

The HPM5300 series has RISC-V core that runs up to 480 MHz, with built-in 288KB SRAM and 1 MB Flash, and is available in 100LQFP, 64 LQFP and 48 QFN. HPM5300 provideshigh computing power and strong control capabilities for applications in Industrial Automation, Renewable Energy, and Automotive Industries.

Performance

The RISC-V core supports double-precision floating-point operations and powerful DSP extensions, with a clock frequency up to 480 MHz.

16KB high-speed cache(l/D Cache) and up to 256KB of Zero-wait nstruction and Data Local Memory (ILM/DLM), greatly improving performance when using external memory.

Motion Control System

Two 8-channel PWM controllers.

Multiple motion sensor intertaces, including Incremental and Absolute Position Sensor Interfaces, Rotary Encoder Interfaces, and Magnetic Encoder Interfaces.

Pulse Position Output Interface and Absolute Position Output Interface.

Motion and Position Control Unit.

Programmable Logic Block (PLB).

Rich Peripherals

Various communication interfaces: High- speed USB with built-in PHY, up to channels of CAN/CAN-FD, and multiple UART, SPI, I2C, and other peripherals.

2 high-precision 16-bit ADC with a sampling rate of 2MSPS, configurable as 12-bit resolution with a conversion rate of 4MSPS, supporting up to 16 analog input pins. 2 programmable gain operational amplifiers, 2 analog comparators, and 212-bit DAC with a sampling rate of 1 MSPS.

Up to 20 channels of 32-bit timers, 3 watchdogs, and an RTC(Real-Time Clock).

Reset

-

Product Introduction

-

Data Manual

-

User Manuals

-

Errata Sheet

-

CAD/CAE Resources

-

Application Documents

Display Result

Name

Type

Language

Date

-

SDK

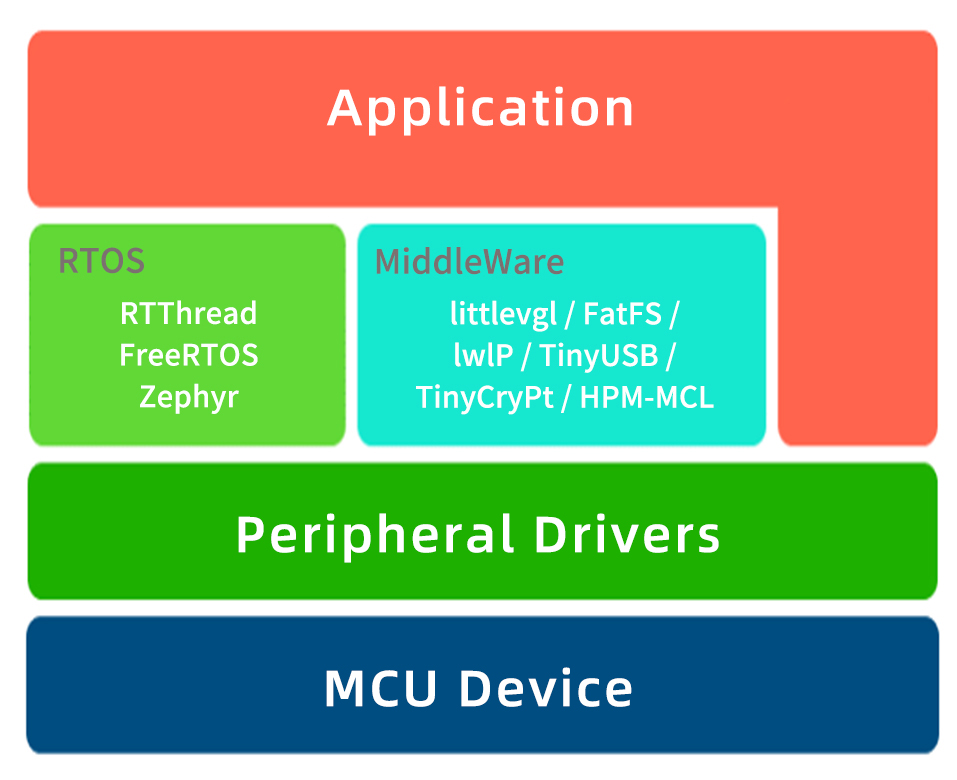

The HPM SDK is a comprehensive software support package launched by HPMicro. It is fully open-source, based on the BSD 3-Clause license, and applicable to all HPMicro microcontroller products.

-

HPM Pinmux Tool

The HPM Pin Multiplexing Tool allows users to assign internal signals to external pins, configure electrical properties, resolve I/O conflicts, and generate pure C source code that can be directly used with the HPM SDK.

-

HPM Manufacturing Tool

The HPM Manufacturing tool is an easy-of-use one-stop tool supporting image editing, and multi-device OTP/image programming via USB/UART.

-

HPM Monitor Studio

HPM Monitor Studio is a real-time monitoring and observation tool launched by HPMicro Semiconductor for MCUs.

-

HPMicro Series Resources

HPMicro Development Materials and Tools

-

Micro Servo Drive Control Integrated Solution

The HPM5300 series microcontroller, as a high-performance motion control MCU, has advantages such as high performance, rich interfaces, smaller packaging, lower cost, and excellent quality. For the HPM5300 series, HPMicro Semiconductor has launched this product level servo drive control solution to evaluate motion control performance. This solution covers most functions of the HPM5300 series chips; Built in position and speed control modes can be matched with various open-loop, semi closed-loop, and closed-loop systems to meet the usage requirements of the vast majority of industries.

-

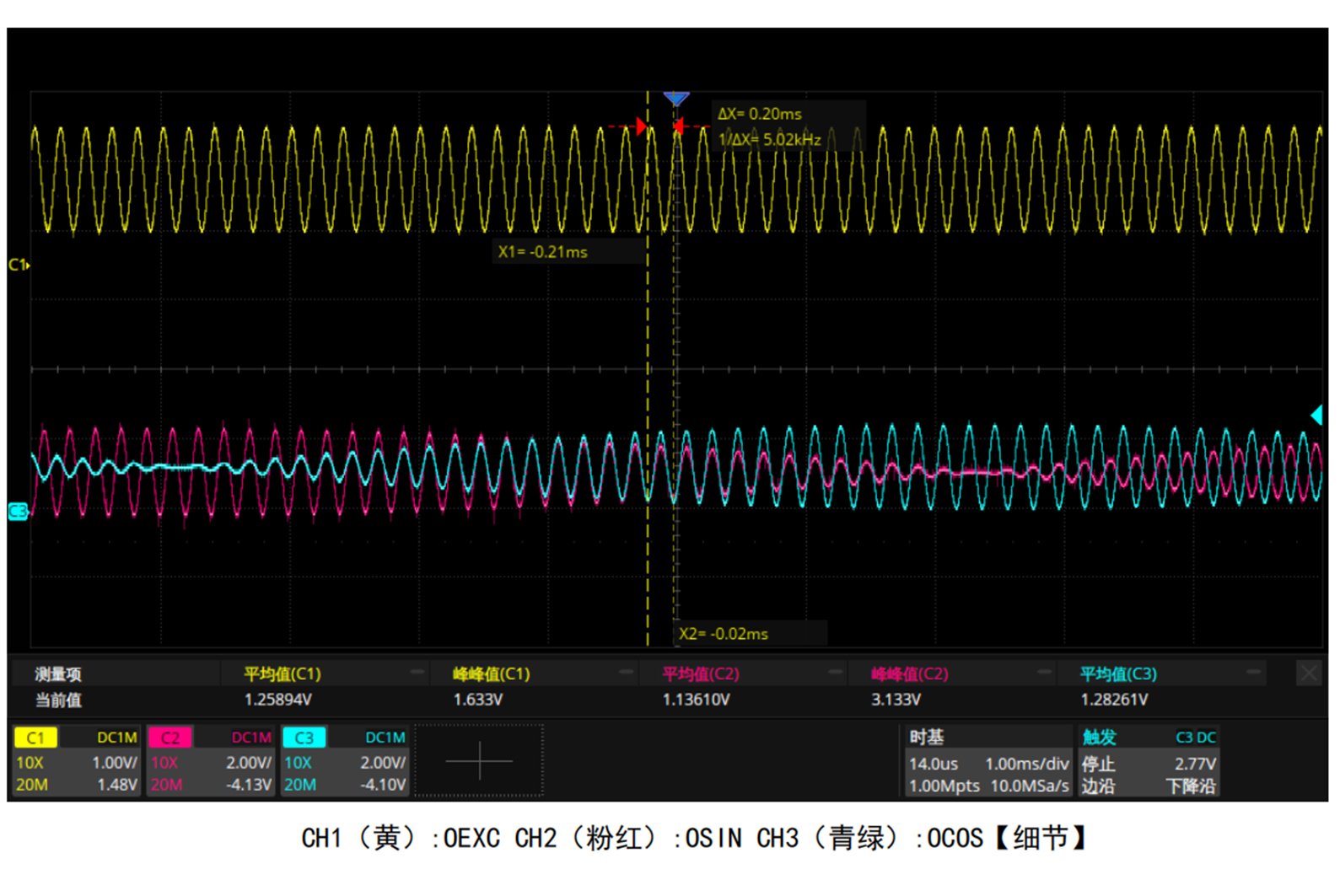

Hardware Decoding Scheme for Resolver

This scheme is a decoding solution that combines the HPM5300 series resolver decoding dedicated peripheral and uses encoders as rotary converters in the field of motor control. It includes software configuration, hardware guidance design, and white box testing documentation. Software configuration is mainly achieved through annotations and white box testing documents, informing readers how to obtain the decoded position of the 5300 series dedicated rotary converter peripheral. The hardware guidance design mainly informs readers about the excitation amplifier and analog front-end circuit of the rotary converter. The white box testing document is mainly based on the ABZ encoder motor testing platform for performance comparison testing.

-

Hpm_motor Library

Hpm_motor is a library file for core algorithms of motor control, which aims to continuously update and improve specific functional algorithms through modular management; For users, there is no need to worry about how the underlying implementation is implemented, which accelerates the development of user programs. Trajectory planning algorithm: When the motor starts and stops, there is a step change in speed. Sudden changes in motor speed may lead to current overload. So, acceleration and deceleration control algorithms are usually used to plan motor speed. The trajectory planning algorithm used in libhpm_motor. a is an S-shaped curve, whose core function is to control the change of acceleration by varying the magnitude of acceleration, ensuring that the acceleration does not suddenly change, making the acceleration and deceleration speed curves smooth, thereby achieving the goal of smooth operation of the motor

-

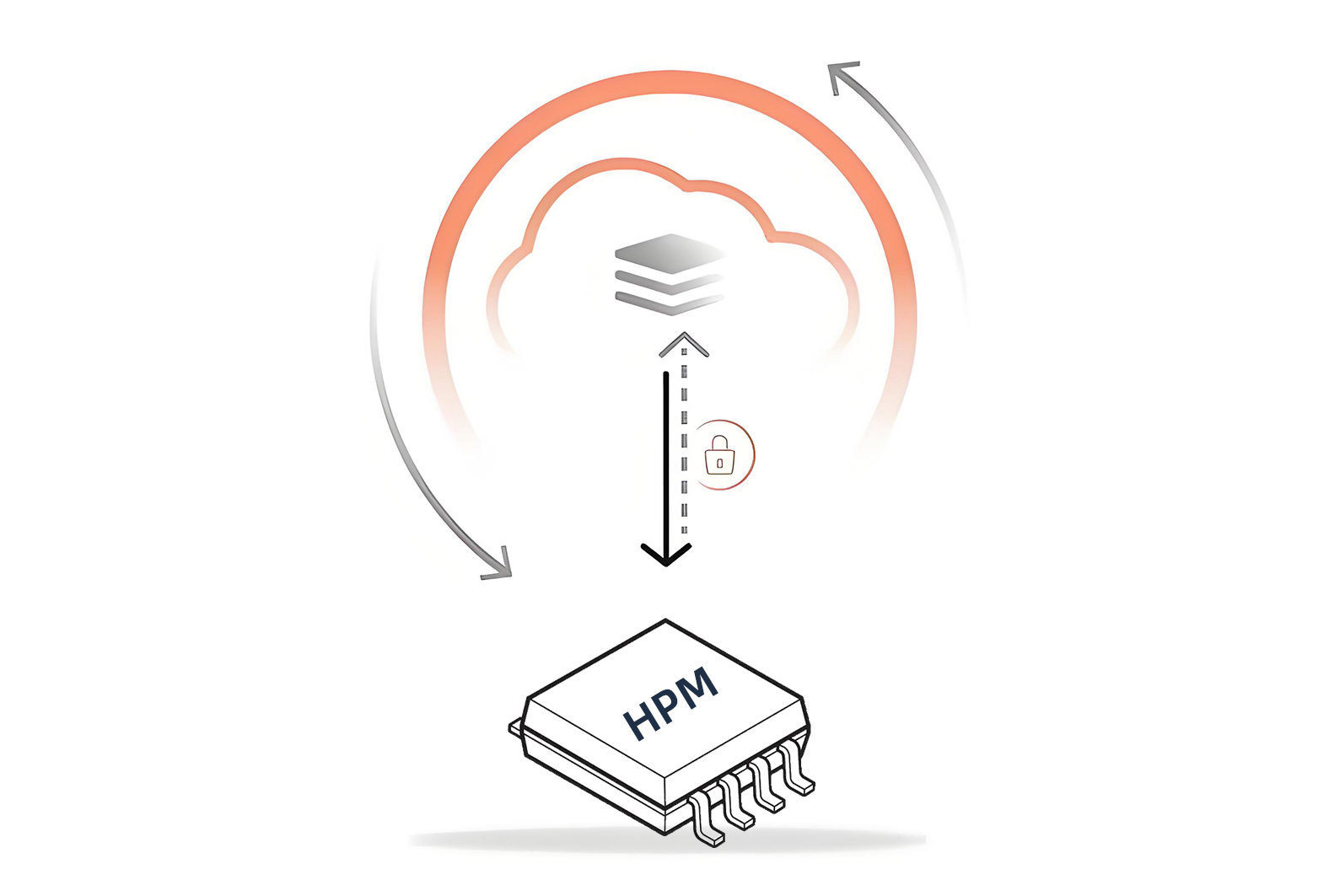

Bootrom OTA Upgrade Solution

This plan mainly introduces how to use the built-in SEC_IMG-OFFSET function of bootrom for OTA upgrade. We use UART xmodem function for OTA upgrade and run encrypted firmware.

-

HPM Level 2 Boot Firmware Upgrade Plan

This solution is a customized Level 2 Boot upgrade solution that supports firmware upgrades in both Level 2 Boot and APP applications. Support upgrade package creation and support different verification algorithms, such as checksum/xor/crc32/sha1/sha256/sm3; Support ping/pang upgrade, second level Boot supports remap jump, user-app only requires one project and linker file; Level 2 Boot supports version verification and intelligent redirection.

-

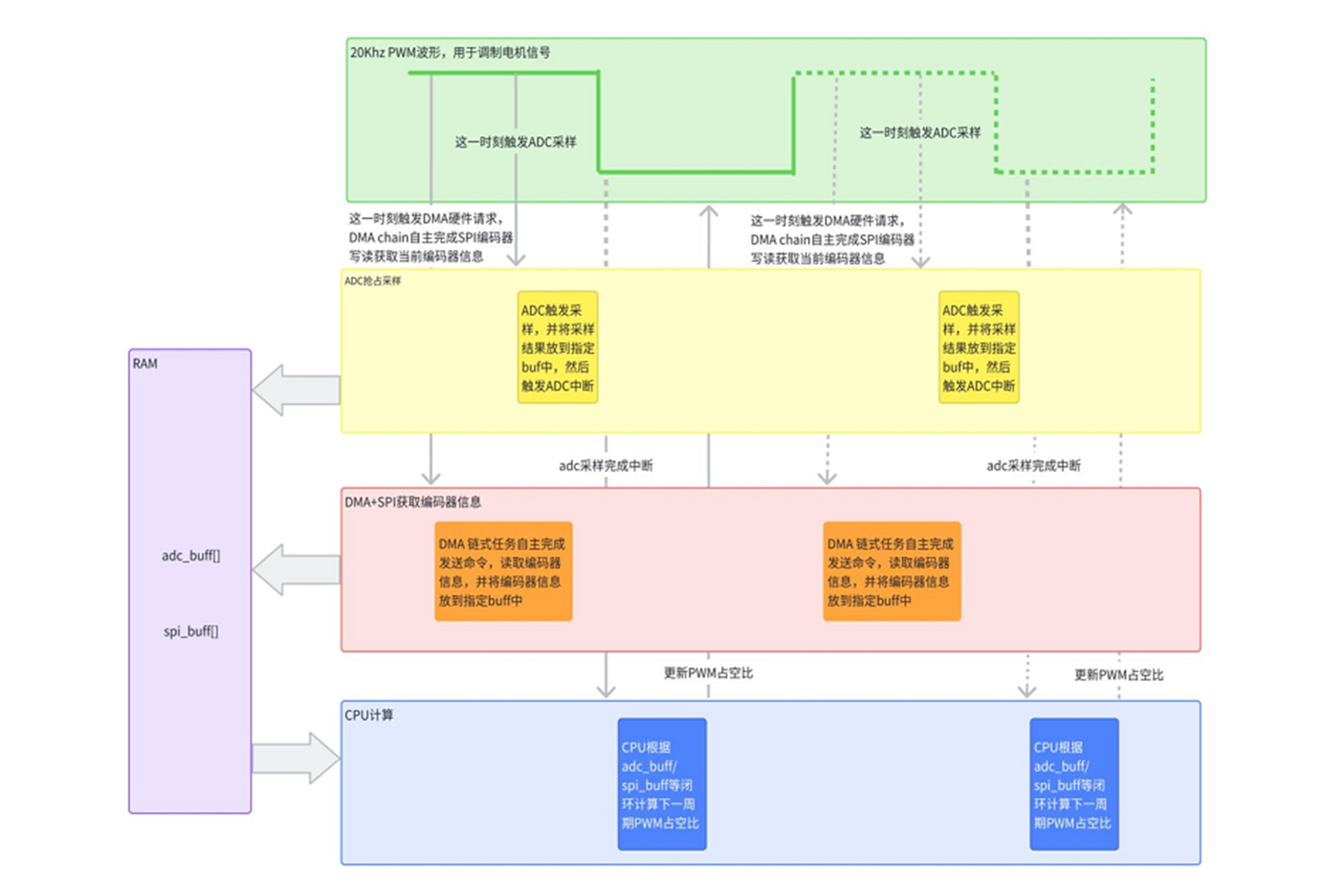

Hpm Motor External Spi Encoder Scheme

This scheme triggers ADC sampling at a specific PWM moment, and at the same time triggers HDMA to operate SPI controller at another specific PWM point. It relies on HDMA chain mode to create a circular linked list, and HDMA automatically completes SPI read and write tasks, storing the read data in the designated memory without CPU involvement. At the same time, the HPM ADC controller also has its own DMA, which stores the sampled data in the designated memory after ADC sampling is completed, and the CPU does not need to participate. Users can directly use the ADC sampling results and SPI encoder information in the ADC sampling completion interrupt to perform subsequent closed-loop algorithms and ultimately adjust the PWM duty cycle for the next cycle.

-

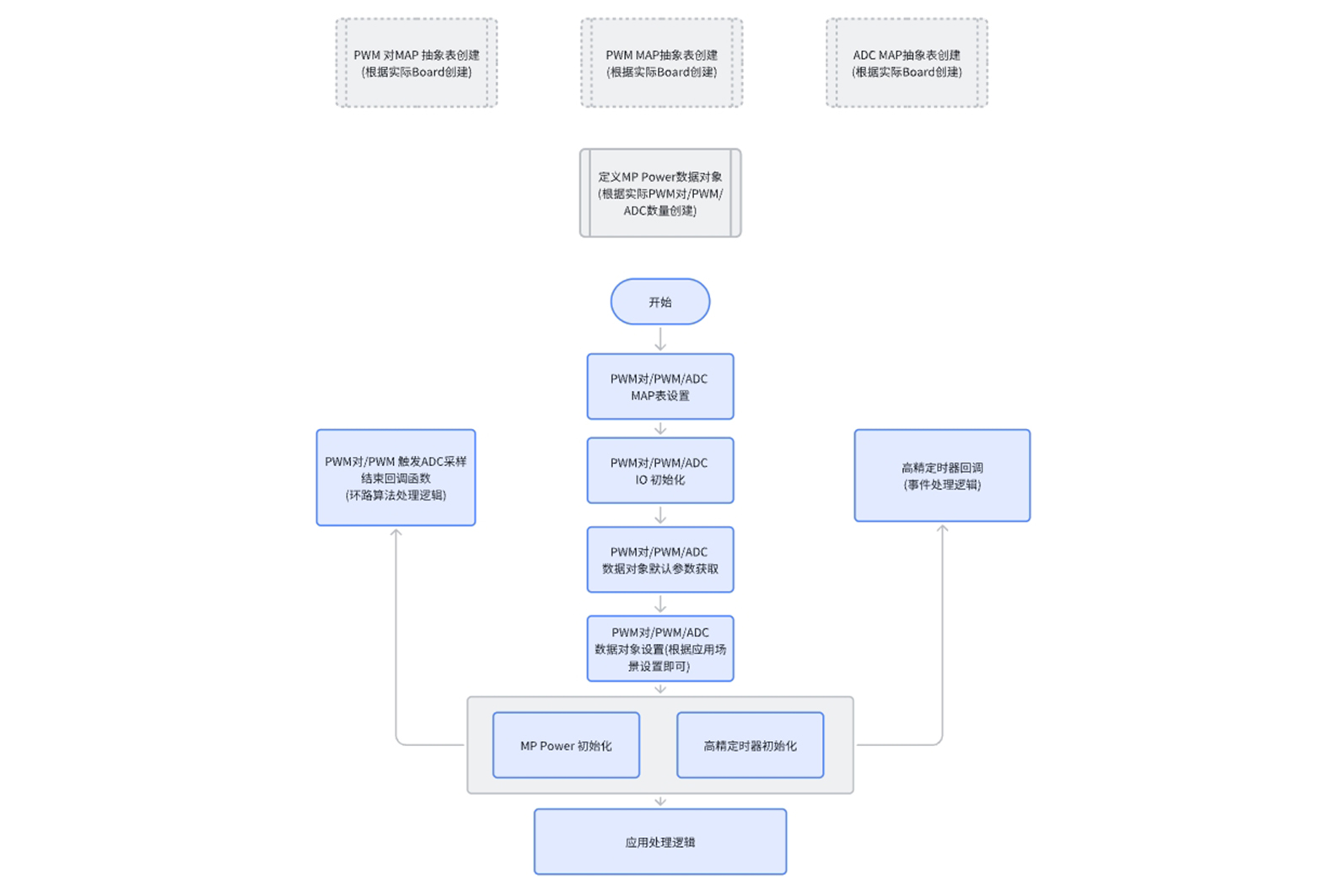

General Software Architecture Solution for Power Supply

The HPM Power solution summarizes the requirements of power management MCU, integrates them into a universal software architecture solution, and provides various API interfaces. The HPM Power Driver API is a driver API interface for power supplies based on the HPM Software Development Kit (HPM SDK) package. The Power API abstracts hardware components such as PWM pairs, PWM, and ADC channels into custom ID numbers, and upper layer applications only need to focus on the abstract ID numbers.

-

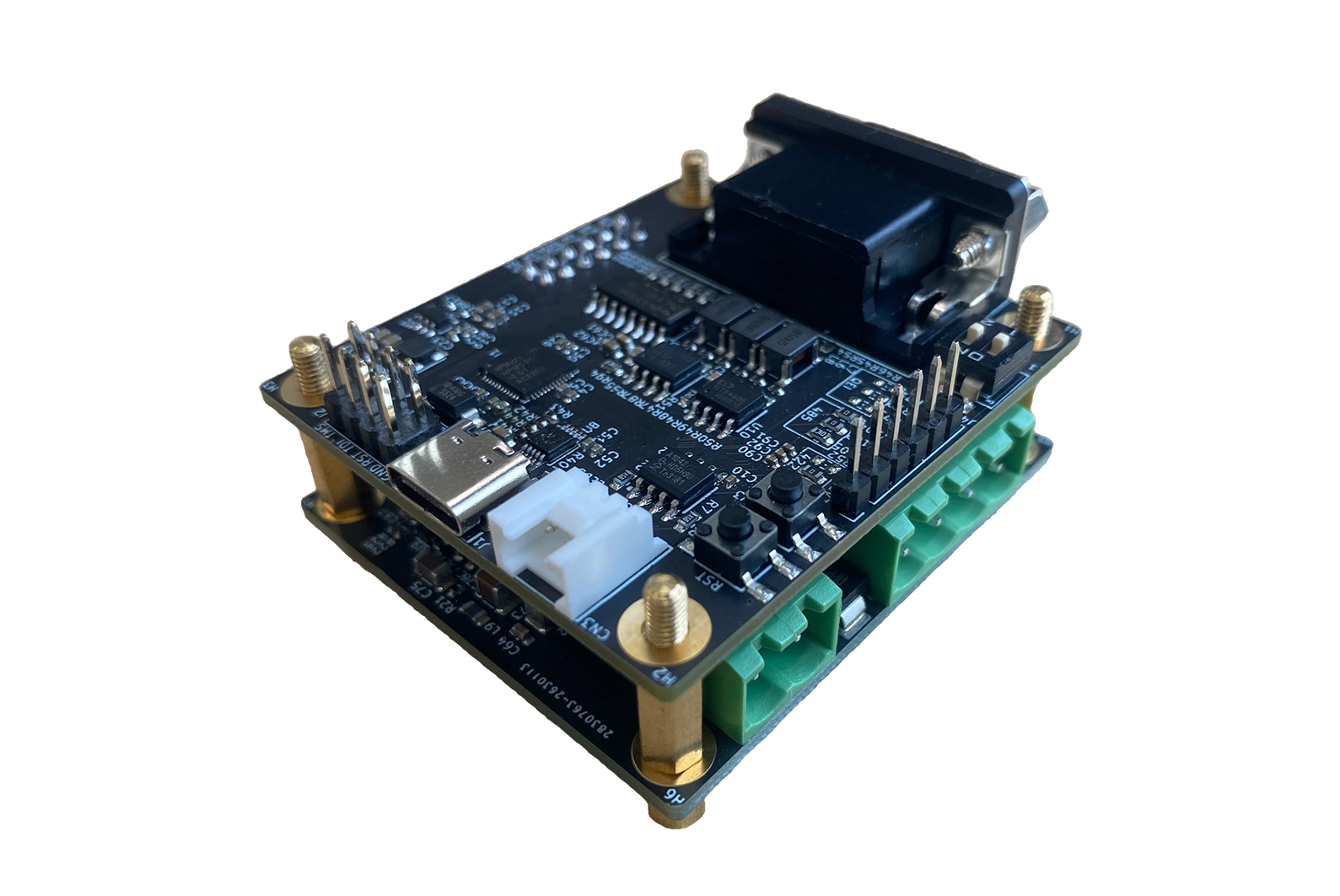

HPM5300EVK

The HPM5300EVK provides a range of interfaces for the HPM5300 microcontroller peripherals, including an ADC input SMA interface and a standard HPMicro motor control and sensor interface. The HPM5300EVK also integrates a 2x20 pin IO expansion interface that connects to most of the HPM5300 MCU's IOs for user evaluation. The HPM5300EVK features an onboard debugger and also offers a standard JTAG interface for connecting with JLINK, DAPLINK, and other debuggers.

-

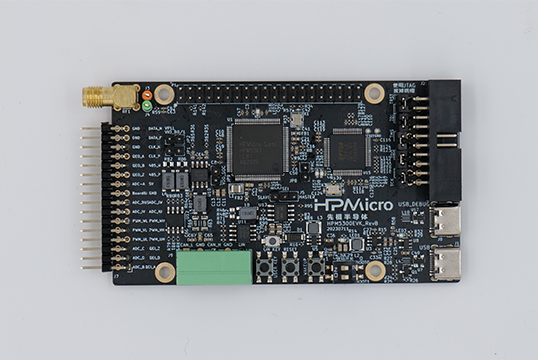

HPM5301EVKLite

The HPM5300EVKLite is an entry-level development board from HPMicro, featuring a 360MHz core frequency, 288KB of RAM, and 1MB of Flash memory. It includes an integrated high-speed USB PHY for USB OTG functionality, a standard 20-pin JTAG interface, a Type-C USB interface, buttons, LEDs, and a standard Raspberry Pi interface, allowing users to easily expand functionality.

-

HPM5361IEG1

Package: QFN48_EP

-

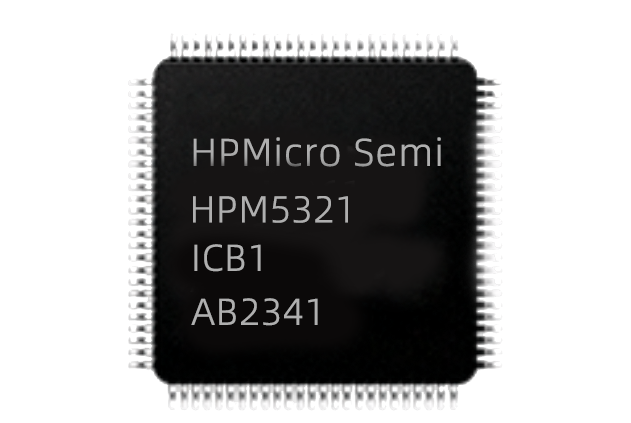

HPM5321IEG1

Package: QFN48_EP

-

HPM5301IEG1

Package: QFN48_EP

-

HPM5321ICB1

Package: LQFP100

-

HPM5321ICF1

Package: LQFP-64

-

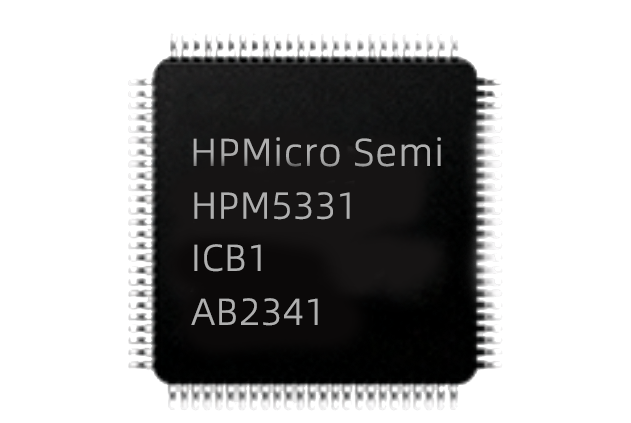

HPM5331ICB1

Package: LQFP100

-

HPM5331ICF1

Package: LQFP-64

-

HPM5331IEG1

Package: QFN48_EP

-

HPM5361ICB1

Package: LQFP100

-

HPM5361ICF1

Package: LQFP-64